Category Archives: Archive by Type

Aluminium Tectonics-Final Presentation-Alvin Amito

At the final presentation, we peeled of the covering from the aluminium. The results were good, and the party from Ash and Lacy was pleased with the simple idea that was, from a business side very appealing, as all the

Aluminium Tectonics-Final Presentation-Alvin Amito

At the final presentation, we peeled of the covering from the aluminium. The results were good, and the party from Ash and Lacy was pleased with the simple idea that was, from a business side very appealing, as all the

Aluminium Tectonics-Final Model-Alvin Amito

For the final model we chose the scale 1:2 instead of 1:1 because it allowed us to be able to show more of the screen inside the 1:1 frame and how it worked, rather than the full scale model. This

Aluminium Tectonics-Final Model-Alvin Amito

For the final model we chose the scale 1:2 instead of 1:1 because it allowed us to be able to show more of the screen inside the 1:1 frame and how it worked, rather than the full scale model. This

Aluminium Tectonics-Test scale model-Alvin Amito

After creating the mock ups, we made a 1:10 scale model to test out the scheme and the Aluminium. This was an interesting and extremely useful experience as several issues were highlighted such as the type of connections we should

Aluminium Tectonics-Test scale model-Alvin Amito

After creating the mock ups, we made a 1:10 scale model to test out the scheme and the Aluminium. This was an interesting and extremely useful experience as several issues were highlighted such as the type of connections we should

Aluminium Tectonics-Second workshop session-Alvin Amito

At the second workshop session we came up with more solid ideas that were based on the themes of music and motion, incorporating elements from the musical instrument, the piano. We decided on creating a screen that resembled a piano

Aluminium Tectonics-Second workshop session-Alvin Amito

At the second workshop session we came up with more solid ideas that were based on the themes of music and motion, incorporating elements from the musical instrument, the piano. We decided on creating a screen that resembled a piano

Ash & Lacy study visit

Presentation of our study visit at Ash & Lacy. Our group looked in particular at the CNC cutting process, as well as the more technical process of preparing files and handling the aluminium sheets on the CNC bed. Razvan Pop

Ash & Lacy study visit

Presentation of our study visit at Ash & Lacy. Our group looked in particular at the CNC cutting process, as well as the more technical process of preparing files and handling the aluminium sheets on the CNC bed. Razvan Pop

Design Development

This week we have presented our proposal of the entrance screen for the new Birmingham Conservatoire. After measuring the opening from a facade elevation provided by the architects of the new building we have decided to create a 1:2 scale model

Design Development

This week we have presented our proposal of the entrance screen for the new Birmingham Conservatoire. After measuring the opening from a facade elevation provided by the architects of the new building we have decided to create a 1:2 scale model

Aluminium Tectonics-Alvin Amito

First week of Workshop sessions. We racked our brains for ideas on how we could clad the Conservatoire building and we came up with these initial models. We focused on the subject of music and movement so that we could

Aluminium Tectonics-Alvin Amito

First week of Workshop sessions. We racked our brains for ideas on how we could clad the Conservatoire building and we came up with these initial models. We focused on the subject of music and movement so that we could

Aluminium Tectonics-Alvin Amito

After observing the complete Ash and Lacy production processes, we were split into groups and produced a presentation focusing on one of the areas, using a range of media and also producing a draft of a response to the next part of

Aluminium Tectonics-Alvin Amito

After observing the complete Ash and Lacy production processes, we were split into groups and produced a presentation focusing on one of the areas, using a range of media and also producing a draft of a response to the next part of

Aluminium Tectonics-Alvin Amito

Our first site visit to Ash & Lacy as an introduction into part 1 of the project, comprising of a presentation into the companies history and current ventures, followed by a general tour of the production sequence involved.

Aluminium Tectonics-Alvin Amito

Our first site visit to Ash & Lacy as an introduction into part 1 of the project, comprising of a presentation into the companies history and current ventures, followed by a general tour of the production sequence involved.

Aluminium Tectonics – Emraan Mayow

ASH & LACY TIMELINE 1857 – Formed First Company – Joseph Ash. 1864 – Joined with John Pierce Lacy to form Ash & Lacy. 1970 – Ash & Lacy Steel Products Formed. 1975 – Floclad Added to Product Range. 1984 – Flospan Buildings Developed and Launched/Dekex Fully Sealed Roof

Aluminium Tectonics – Emraan Mayow

ASH & LACY TIMELINE 1857 – Formed First Company – Joseph Ash. 1864 – Joined with John Pierce Lacy to form Ash & Lacy. 1970 – Ash & Lacy Steel Products Formed. 1975 – Floclad Added to Product Range. 1984 – Flospan Buildings Developed and Launched/Dekex Fully Sealed Roof

Aluminium Tectonics – Benjamin James

Finally, the ‘cross louvre’ design for our solar shading system is complete. It has developed through all stages with initial designs being inspired by the simple experience of walking through a wood. The experience led to the idea of manipulating

Aluminium Tectonics – Benjamin James

Finally, the ‘cross louvre’ design for our solar shading system is complete. It has developed through all stages with initial designs being inspired by the simple experience of walking through a wood. The experience led to the idea of manipulating

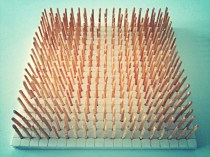

Aluminium techtonics – Final product – Stanley Fu

After many tests with cardboard and aluminium, the final produce was ready to be made. A 4x4cm wooden frame was used to support the cladding system which would be build at a scale of 1:2. We built the model high

Aluminium techtonics – Final product – Stanley Fu

After many tests with cardboard and aluminium, the final produce was ready to be made. A 4x4cm wooden frame was used to support the cladding system which would be build at a scale of 1:2. We built the model high

Aluminium Tectonics – Kimran Farooq

Our light studies show that designs 2 and 3 work most effectively as they reduce the amount of light reflecting from the facade; they reduce the amount of light entering through the windows and they don’t completely block the view

Aluminium Tectonics – Kimran Farooq

Our light studies show that designs 2 and 3 work most effectively as they reduce the amount of light reflecting from the facade; they reduce the amount of light entering through the windows and they don’t completely block the view

You must be logged in to post a comment.